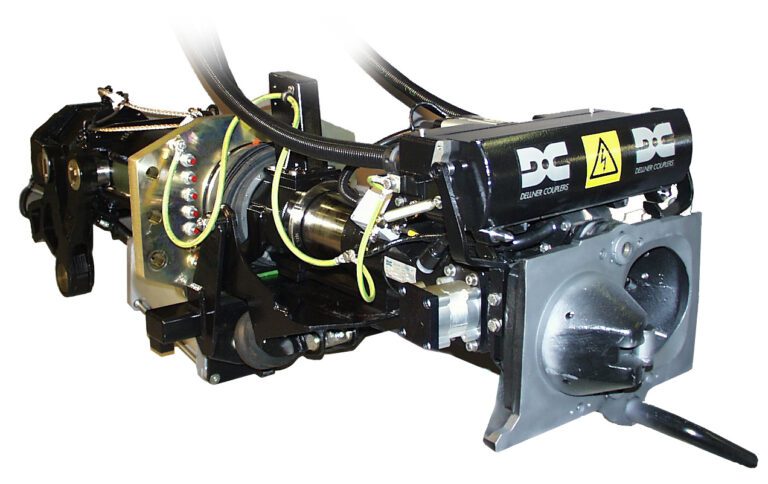

Our story begins in Sweden in 1941. Its main protagonist is the engineer Jan Dellner. Over the years, Jan had made a name for himself in Sweden, as an expert in and salesman of railway couplings. One of his most important business partners is the Swedish State Railways (SJ)- Sweden’s most important rail operator.

In 1941, SJ makes him an offer that is going to change his future forever: Swedish State Railways asks him if he could be their new supplier of automatic couplers for SJ trains. Automatic couplers were highly innovative at the time. Jan Dellner agrees and eventually develops the first automatic coupler “Made in Sweden” with his “Dellner Engineering Office”.